DIE CASTLund Manufacturing features both aluminum and zinc die cast machines, ranging in size from 200 - 800 tons. Their range of machines helps them efficiently produce just about any casting you might need.

Die casting, as a process, presents numerous variables that can affect the quality of a casting. Lund's staff has many years of experience which allows them to pinpoint and correct any irregularities before they occur. Lund will work closely with your design team to make sure that your products' design lends itself well to die casting. Lund Manufacturing also features an on-site maintenance crew that keeps preventative maintenance up to date and is quickly able to repair any issues that might occur. |

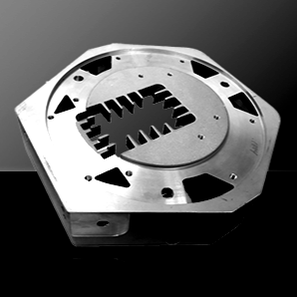

CNCLund's CNC's allow them to achieve any tolerance that your product might require. These CNC's also make it possible to quickly turn product that might otherwise require more labor-intensive processes.

Programming machines and building fixtures are done in-house. This enables Lund to keep costs low and quickly start new projects. Lund's CNC abilities do not only have to be used for castings that they produce but they can also machine castings produced elsewhere (i.e. sand castings, investment castings, etc.) Lund's machining expertise and competitive cost structure allow them to be a competitive machining option for current and future customers. |

POWDER COATOne of the more popular value-added operations that Lund Manufacturing offers is powder coating. This in-house capability to add color to customers' products lends itself well to cost containment and effective design-for-manufacturing.

Lund is fluent in die casting and powder coating and knows the questions to ask to help steer you in the right direction. Lund's powder coat system provides a 5-station wash system, quick paint changes, robotic and manual powder application, and the ability to paint statically or via overhead conveyor system. All of this gives Lund the ability to minimize cost and shorten lead time in relation to paint finish. |

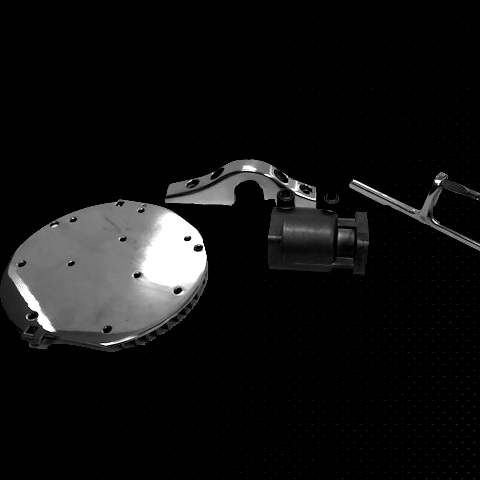

TOOLINGLund begins with your 3D part models and works with the tool builders to provide you with a tool design before steel is ever cut.

Lund offers both domestic and overseas tooling options to help keep tooling costs competitive while still providing needed quality. Runner and overflow systems are determined based on the needs and complexity of the customers' part. Sometimes difficult or more complex parts need to have more than just tool designer experience to ensure the parts come out right. In those cases Lund works closely with flow analysis software providers to make sure the part comes out perfect the first time. Lund features an in-house tool department to clean, repair, and maintain your tooling investment. |

SECONDARY OPERATIONSPart finishes always seem to be the last and most pressing concern for customers. Fortunately, Lund produces a variety of components whose appearances and functions range from "mill finish" to "class-A" to simply "it can't leak!".

From tractor and hydraulic parts to theatrical lighting housings to office furniture components, each customer demands specific finishes and purposes that Lund can achieve. Under one roof you will find:

Lund currently supplies to customers large and small, domestically and abroad. Please let us know how we can service your manufacturing needs. |